Sound Moderators

Custom Made Rifles

Roedale Stocks

Calibers reamers

Services + Prices

About RP

Gallery

Dealers

Testamonials

Links

Delta Accessories

Roedale Delta Ultralight Standard Baffles are accessories for Delta Ultralight and Delta Pro Sound Moderators. 1 baffle increases the peak noise reduction by around 2.5dB and increases the length of the moderator by 20mm

Roedale Delta Ultralight Standard Baffles are accessories for Delta Ultralight and Delta Pro Sound Moderators. 1 baffle increases the peak noise reduction by around 2.5dB and increases the length of the moderator by 20mm

As with all Delta Ultralight components, each part is manufactured from the highest grade high strength aluminium alloy used in the aerospace and defence industries. Parts are CNC machined from solid billets. The surfaces are hardened and coated with a hardcoat-anodizing finish to Mil-Spec type III matt black. This coating lends numerous functional qualities to aluminium components.

Wear-resistance and hardness: The high wear-resistance is based on the hardness and the morphology of the aluminium oxide coating. The attainable hardness of the layer lies between 400 and 500 HV0,025.

Heat conductivity: The heat conductivity amounts to from around 1/10 to 1/30 of the heat conductivity of the base material.

Temperature resistance: Hardcoat layers withstand brief temperature peaks to 2,200 K.

Impact Resistance: The impact resistance complies with ISO 2376 and amounts to 50 µ m: 1213V.

The aim of this coating procedure is functionality and not beauty. Minimum colour differences on the surface may occur between batches.

Delta Ultralight Stainless TiAIN Baffles are accessories for Delta Ultralight and Delta Pro Sound Moderators. 1 baffle increases the peak noise reduction by around 2.5dB and increases the length of the moderator by 20mm. The baffles are manufactured from ordnance grade stainless steel and the TiAIN coated. They are to be used as an accessory for magnum calibers, high volume shooting or for increased longivity.

Delta Ultralight Stainless TiAIN Baffles are accessories for Delta Ultralight and Delta Pro Sound Moderators. 1 baffle increases the peak noise reduction by around 2.5dB and increases the length of the moderator by 20mm. The baffles are manufactured from ordnance grade stainless steel and the TiAIN coated. They are to be used as an accessory for magnum calibers, high volume shooting or for increased longivity.

Roedale Delta Ultralight Compact Baffles are accessories for Delta Ultralight and Delta Pro Sound Moderators. 1 baffle increases the peak noise reduction by around 2dB and increases the length of the moderator by 10mm

Roedale Delta Ultralight Compact Baffles are accessories for Delta Ultralight and Delta Pro Sound Moderators. 1 baffle increases the peak noise reduction by around 2dB and increases the length of the moderator by 10mm

As with all Delta Ultralight components, each part is manufactured from the highest grade high strength aluminium alloy used in the aerospace and defence industries. Parts are CNC machined from solid billets. The surfaces are hardened and coated with a hardcoat-anodizing finish to Mil-Spec type III matt black. This coating lends numerous functional qualities to aluminium components.

Wear-resistance and hardness: The high wear-resistance is based on the hardness and the morphology of the aluminium oxide coating. The attainable hardness of the layer lies between 400 and 500 HV0,025.

Heat conductivity: The heat conductivity amounts to from around 1/10 to 1/30 of the heat conductivity of the base material.

Temperature resistance: Hardcoat layers withstand brief temperature peaks to 2,200 K.

Impact Resistance: The impact resistance complies with ISO 2376 and amounts to 50 µ m: 1213V.

The aim of this coating procedure is functionality and not beauty. Minimum colour differences on the surface may occur between batches.

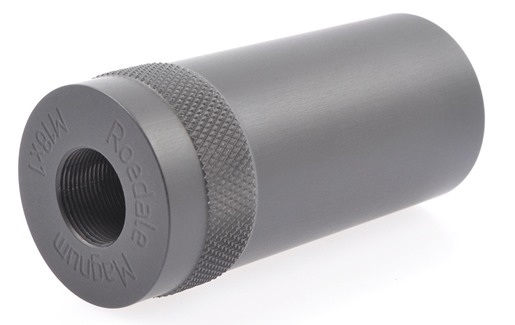

Delta Magnum Expansion Chamber

is an accessory for the Delta Ultralight Moderator. It can be used to upgrade a standard ultralight moderator for use with a magnum caliber or to achieve increased peak sound reduction on standard calibers. Fitting a Delta Ultralight with a Magnum Expansion chamber instead of an Ultralight chamber increases noise reduction be upto 3dB.

As with all Delta Ultralight components, each part is manufactured from the highest grade high strength aluminium alloy used in the aerospace and defence industries. Parts are CNC machined from solid billets. The surfaces are hardened and coated with a hardcoat-anodizing finish to Mil-Spec type III matt black. This coating lends numerous functional qualities to aluminium components.

Wear-resistance and hardness: The high wear-resistance is based on the hardness and the morphology of the aluminium oxide coating. The attainable hardness of the layer lies between 400 and 500 HV0,025.

Heat conductivity: The heat conductivity amounts to from around 1/10 to 1/30 of the heat conductivity of the base material.

Temperature resistance: Hardcoat layers withstand brief temperature peaks to 2,200 K.

Impact Resistance: The impact resistance complies with ISO 2376 and amounts to 50 µ m: 1213V.

The aim of this coating procedure is functionality and not beauty. Minimum colour differences on the surface may occur between batches.

Delta Pro Expansion Chamber

is an accessory for the Delta Ultralight Moderator. It can be used to convert the standard ultralight moderator bafflestack into a back over barrel moderator. This achieves slightly increased peak sound reduction on standard calibers and shortens the OAL by almost 50mm.

As with all Delta Ultralight components, each part is manufactured from the highest grade high strength aluminium alloy used in the aerospace and defence industries. Parts are CNC machined from solid billets. The surfaces are hardened and coated with a hardcoat-anodizing finish to Mil-Spec type III matt black. This coating lends numerous functional qualities to aluminium components.

Wear-resistance and hardness: The high wear-resistance is based on the hardness and the morphology of the aluminium oxide coating. The attainable hardness of the layer lies between 400 and 500 HV0,025.

Heat conductivity: The heat conductivity amounts to from around 1/10 to 1/30 of the heat conductivity of the base material.

Temperature resistance: Hardcoat layers withstand brief temperature peaks to 2,200 K.

Impact Resistance: The impact resistance complies with ISO 2376 and amounts to 50 µ m: 1213V.

The aim of this coating procedure is functionality and not beauty. Minimum colour differences on the surface may occur between batches.